Biodiesel Production and Distribution

Production

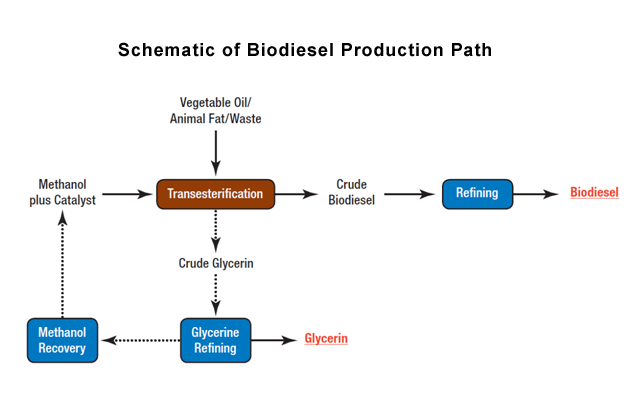

Biodiesel is produced from vegetable oils, yellow grease, used cooking oils, or animal fats. The fuel is produced by transesterification—a process that converts fats and oils into biodiesel and glycerin (a coproduct). Approximately 100 pounds of oil or fat are reacted with 10 pounds of a short-chain alcohol (usually methanol) in the presence of a catalyst (usually sodium hydroxide [NaOH] or potassium hydroxide [KOH]) to form 100 pounds of biodiesel and 10 pounds of glycerin (or glycerol). Glycerin, a coproduct, is a sugar commonly used in the manufacture of pharmaceuticals and cosmetics.

Raw or refined plant oil, or recycled greases that have not been processed into biodiesel, are not biodiesel and should not be used as a vehicle fuel. Fats and oils (triglycerides) are much more viscous than biodiesel, and low-level vegetable oil blends can cause long-term engine deposits, ring sticking, lube-oil gelling, and other maintenance problems that can reduce engine life. (See Straight Vegetable Oil as a Diesel Fuel?)

Research is being conducted on developing algae as a potential biodiesel feedstock. It is expected to produce high yields from a smaller area of land than vegetable oils.

Renewable diesel is distinct from biodiesel and is produced through a different process.

Distribution

Biodiesel is distributed from the point of production to fuel terminals and wholesalers by truck, train, or barge. B5 is sometimes shipped by pipeline. Most biodiesel distributors will deliver B20 or B100 depending on the retailer's preference.