Filling CNG Fuel Tanks

CNG Fueling Animation

Use this interactive animation to learn how fill speed and temperature affect the final fill volume.

Unlike liquid fuel, which consistently maintains the same volume across a broad range of temperatures, compressed natural gas (CNG) will expand and contract significantly with a change in temperature. Heat causes CNG fuel molecules to expand, and cold causes the molecules to become denser. Therefore, under industry standard conditions (pressure and temperature), a CNG tank may typically contain 20 gasoline gallon equivalents. However, on a hot day the CNG molecules will expand, and the tank may only be able to accommodate up to 75% (or less) of its design potential under cooler temperature conditions.

Fueling equipment has been optimized with fast-fill dispensers that are equipped with a temperature compensation feature to help maintain temperatures to industry standard conditions and assist vehicles to achieve maximum fill of their fuel tanks.

The amount of CNG that can be stored in a vehicle's tank varies due to multiple factors:

-

Fueling rate: As the rate of CNG fueling increases, the temperature of the fuel molecules also increases dramatically. As the fuel warms up, it expands and becomes less dense, resulting in less energy per volume when the fuel system reaches the industry-rated pressure. Therefore, it is usually more efficient to achieve a fuller fill with a slower "time-fill" method rather than a "fast-fill" process. This allows the CNG fuel molecules to remain in a dense state rather than expanding from the heat created by the rapid movement and compression of CNG into the tank.

-

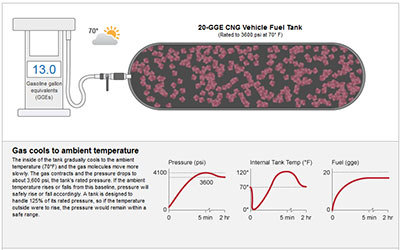

Ambient temperature: The outside temperature also affects the temperature of the CNG. At higher temperatures, CNG is less dense and therefore does not contain as much energy per unit volume as it would in a compressed state at a lower temperature. When the CNG is stored in warm ambient temperatures, the fuel molecules expand and no longer contain as much energy as they would at lower temperatures.

-

Pressure rating: The typical industry standard for CNG fueling system pressure is 3,600 pounds per square inch (psi). Some systems in the United States and many systems overseas are rated at 3,000 psi. These fill pressures are based on a 70ºF ambient temperature. The CNG fuel tanks are designed to withstand up to 125% of their operating pressure. Therefore, a 3,000-psi tank can technically be filled to 3,750 psi, and a 3,600-psi tank can be filled to 4,500 psi. This allows a tank to be filled to a higher pressure on hot days when the gas is expanding, as well as compensate for the heat associated with the compression of the natural gas. A good rule of thumb is that for every 10ºF plus or minus 70ºF, the pressure will increase or decrease by 100 psi.

-

Tank type: There are four types of CNG tanks (Type 1–4). The type designation is based on the design and production method, including the tank's liner material. The materials also regulate the temperature inside of the tank and therefore affect how much CNG it can contain based on the defined limits. For example, carbon fiber tanks retain more heat compared to steel tanks and may reduce the capacity of the CNG due to the fuel molecules expanding under warmer conditions.