Biodiesel Emissions

When used as a vehicle fuel, biodiesel can have some emissions benefits over gasoline and conventional diesel fuel. The greenhouse gas emissions benefits of biodiesel are especially significant, because the carbon dioxide released during fuel combustion is offset by the carbon dioxide sequestered by the plants from which biodiesel is produced.

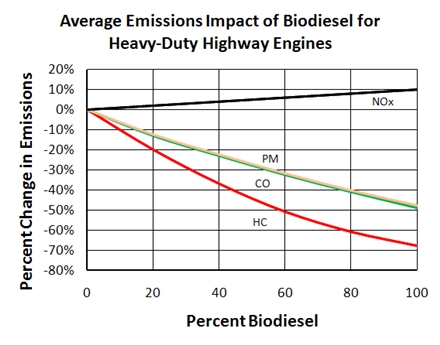

Analysis completed by the Environmental Protection Agency (EPA) in 2002 compiled the most robust data set on biodiesel tailpipe emissions from heavy-duty engines. This study was comprised primarily of data from vehicles manufactured prior to 1997 and does not take into account the significant recent advancements in diesel engine controls and emissions aftertreatment technologies. The findings were published in A Comprehensive Analysis of Biodiesel Impacts on Exhaust Emissions, an EPA report that analyzes data from 39 studies. It concludes that biodiesel decreases emissions of particulate matter (PM), carbon monoxide (CO), and hydrocarbons (HC) commensurately with its blend level, as shown in the figure below.

Source: EPA 2002

EPA's study found a slight increase in oxides of nitrogen (NOx) emissions—approximately 2% for B20. However, Effects of Biodiesel Blends on Vehicle Emissions, published by the National Renewable Energy Laboratory (NREL), presented data and analysis suggesting that B20 has no statistically significant net impact on NOx emissions. A report published by SAE in 2009 . Bio-distillate Transportation Fuels 2-Emissions Impacts—corroborated the NREL results and found the NOx increase at B100 to be in the 2% to 3% range.

These results may not accurately reflect the improved emissions performance of today's high-tech diesel vehicles. Integration of sophisticated engine controls—as well as fueling and exhaust aftertreatment devices—are the determining factors governing how clean a vehicle or engine will be. Use of alternative fuels like B20 or B100 can reduce dependency on petroleum and be environmentally beneficial but their use may not necessarily reduce tailpipe emissions.

| Air Pollutant | Percent Change for B20 |

|---|---|

| NOx | 0.0 |

| PM | -10.1 |

| Carbon Monoxide | -11.0 |

| Hydrocarbons | -21.1 |

Lifecycle Emissions and Petroleum Use

Life cycle analysis is a technique used to assess the environmental impacts of all stages of a product's life, including raw material extraction, processing, manufacturing, distribution, use, and disposal or recycling. When comparing fuels, a life cycle analysis may focus on particular portions of a fuel's life cycle, such as from extraction-to-use or well-to-wheels, to determine the merits or problems associated with each fuel.

Life cycle analysis completed by the National Renewable Energy Laboratory, and later by Argonne National Laboratory, found that greenhouse gas emissions for 100% biodiesel (B100) could be more than 52% lower than those from petroleum diesel. These analyses also showed that biodiesel may reduce petroleum use by more than 88% throughout its life cycle. Therefore, reducing petroleum diesel use reduces U.S. dependency on foreign sources of transportation fuel.

Sources:

Life cycle Assessment of Energy and Greenhouse Gas Effects of Soybean-Derived Biodiesel and Renewable Fuels

An Overview of Biodiesel and Petroleum Diesel Life Cycles